The research team has successfully invented a novel edible food packaging film

Biodegradable packaging for a sustainable future

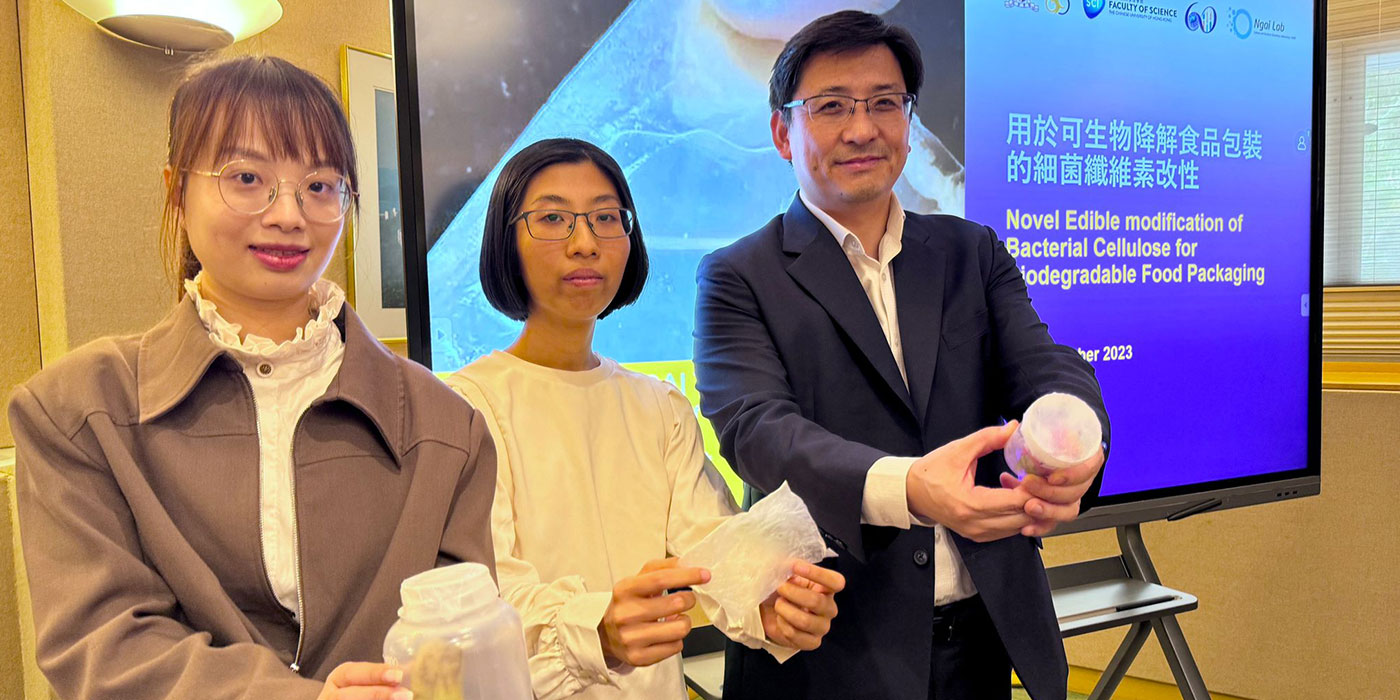

A CUHK research team led by Professor Ngai To, Assistant Dean (Research) from the Faculty of Science and Professor in the Department of Chemistry, has made a breakthrough in the development of a new generation of biodegradable materials to replace plastics. Professor Ngai’s team has successfully invented a novel edible food packaging film. The findings have been recently published in the prestigious international scientific publication Journal of the Science of Food and Agriculture.

Plastic bags are the most commonly used packaging material in daily life, thanks to features such as their low weight, durability, corrosion resistance and low cost. However, they take hundreds of years to decompose, and indiscriminate disposal of plastic bags has led to severe environmental pollution.

Apart from causing the deaths of animals due to ingestion of plastic waste, microplastics entering the food chain also disrupt the entire ecosystem. In the face of escalating environmental issues, researchers are seeking biodegradable biomass alternatives, such as plant fibres and biopolymers derived from agricultural waste.

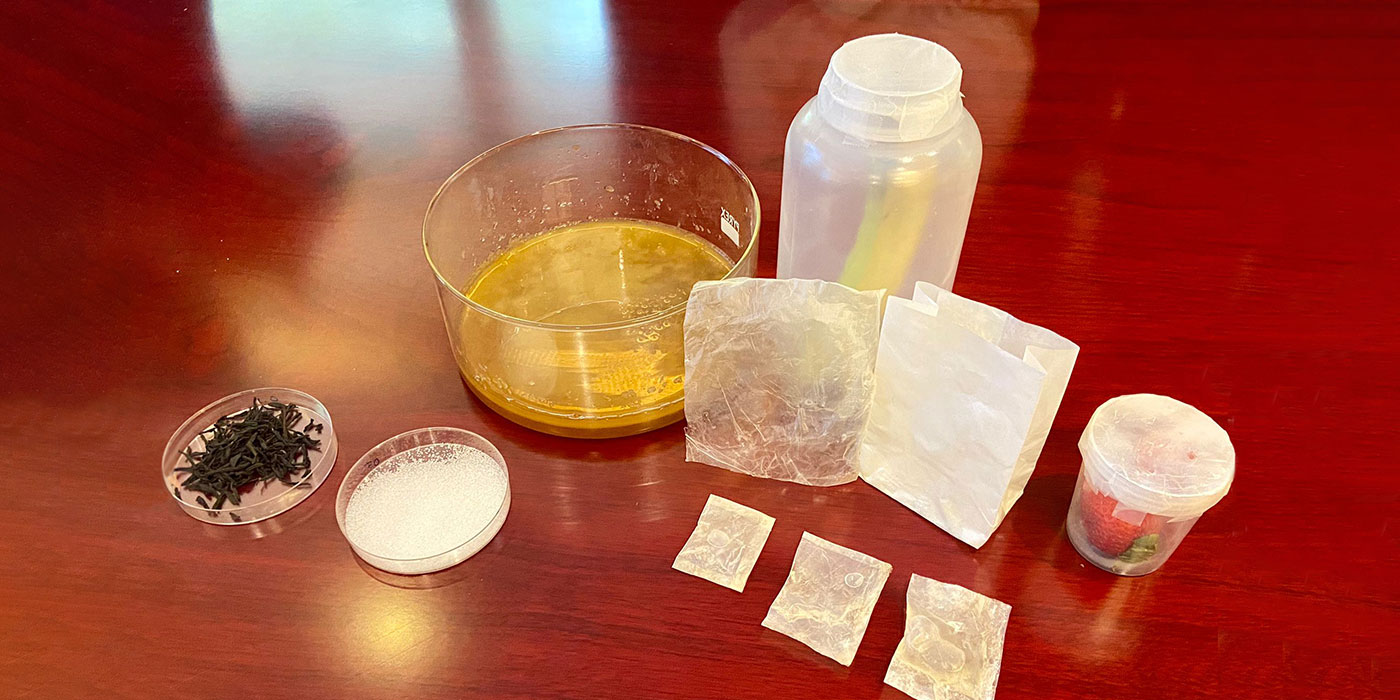

The research team has discovered that bacterial cellulose can be used as an edible food packaging film. This novel bio-based packaging material exhibits similar stretching properties to plastic bags, can degrade in the natural environment, and is harmless to humans, to the extent that it is edible. The symbiosis of Komagataeibacter xylinus bacteria and yeast, commonly known as kombucha, is used to produce bacterial cellulose (BC). By genetically modifying the bacteria to secrete cellulose fibres and then form biofilms, BC can be produced through microbial fermentation, without the need to harvest cellulose from the plant cell walls of trees.

The research team found that composite materials composed of kombucha BC-based film, soy protein and alginate salt possess multiple advantages, including edibility, mechanical stability, transparency, flexibility, high barrier properties and high thermal stability. Unlike materials such as polylactic acid (PLA), a common biodegradable plastic material derived from corn starch that needs to be decomposed in a compost environment at a specific temperature, BC films can completely biodegrade within one to two months in ordinary natural environments. The BC film fabricated using this method is free from toxic solvents and additives, and exhibits stability in both dry and wet conditions. The production process is simple. It has the potential to replace commercial plastics, its lack of toxicity making it particularly suitable for food packaging.

Professor Ngai said: “This material is completely safe for consumption, and even if it enters aquatic ecosystems, it does not cause any toxicity in aquatic life such as sea turtles. The research on BC films is just the beginning, and we will continue to optimise their multifunctionality to develop new films and coatings, especially by enhancing their thermoplastic properties, for broader applications.” Professor Ngai also expressed hope that this new BC food packaging film can provide an environmentally friendly alternative that helps the local food and beverage industry to comply with the upcoming regulations on disposable plastic tableware.

The full text of the research paper can be found at: https://onlinelibrary.wiley.com/doi/10.1002/jsfa.12758