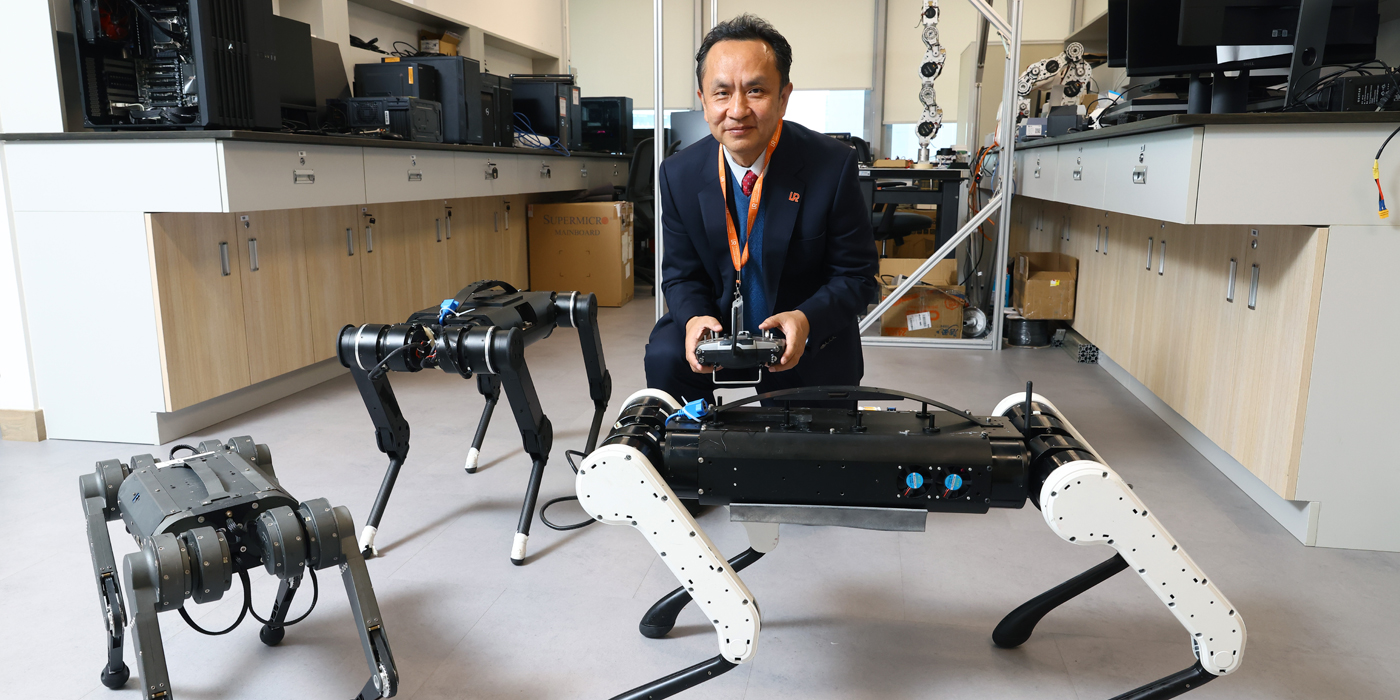

Professor Liu Yun-hui

Robots for the workplace

The Hong Kong Centre for Logistics Robotics innovates to drive efficiency

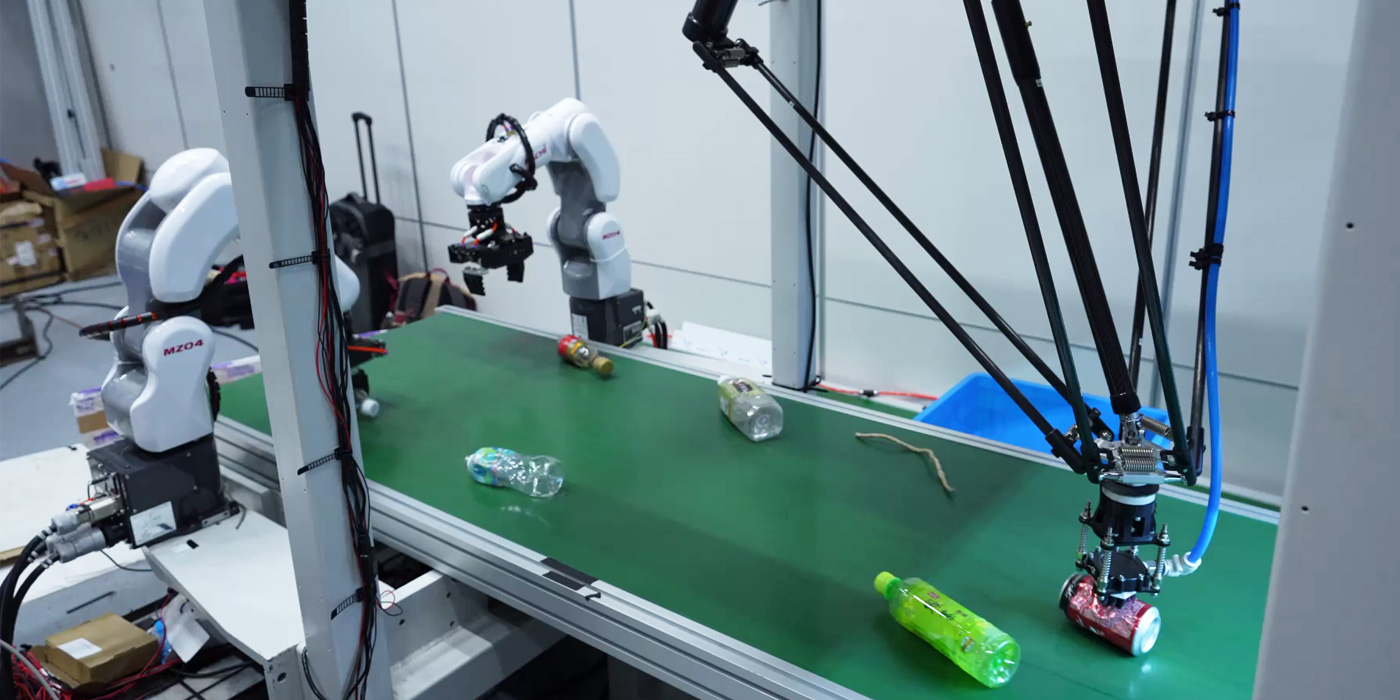

Two years ago, Professor Liu Yun-hui visited with his research team a metal recycling plant in Yuen Long, a messy environment filled with smells of waste.

“They were rather bad working conditions,” recalls Professor Liu, from the Department of Mechanical and Automation Engineering (MAE) and also Director of the Hong Kong Centre for Logistics Robotics at CUHK (the Centre). “The workers were picking up small aluminium pieces from piles of scrap metal by hand for recycling, which was tedious physical work. It was difficult for the plant to hire enough workers.”

He and Professor Chen Fei, also a principal investigator of the Centre, had been invited by the plant owner to see how robots could help make operations more efficient.

“We went on to visit many other recycling factories in the New Territories. The more we saw, the more we believed there was great potential for getting robots to sort wastes,” he says.

Building on technologies including grasping and sensing, which the Centre’s team had been researching for years, they invented an intelligent, high-speed solid-waste sorting system. Using eight such systems, the plant in Yuen Long, processing 150 tonnes of scrap metal a day, is able to save more than 70 per cent of its costs compared to deploying workers for the same task. It can recover its investments in the systems in 11 months.

The technology has been licensed to Professor Chen’s startup SOTA Robotics, which was set up last year. It is Hong Kong’s first provider of automated robotic waste sorting solutions.

“We often go out to talk to industrial leaders in Hong Kong and the Greater Bay Area to understand their needs. When we see a potential demand, we explore the technology for commercialisation.”

Pooling expertise

The Centre, founded in 2020 under the Hong Kong government’s InnoHK initiative, focuses on the research and development of robotics and artificial intelligence technologies for the “future workplace” as well as innovative solutions to the problems of manpower shortage and high labour costs in the logistics industry.

The Centre runs four research programmes: robust sensing and perception; human-robot collaboration; smart manipulation robots; and unmanned logistics vehicles. They are steered by 15 principal investigators from CUHK and five from University of California, Berkeley.

The head of the Centre, Professor Liu has long translated his research into real-world applications, his signature innovation being the world’s leading vision-based autonomous forklift used in warehouses. Hundreds of automated guided vehicle (AGV) projects have been deployed around the world by VisionNav Robotics set up by him and his students. He also helped develop China’s largest smart warehouse for Cainiao, a logistics firm owned by e-commerce giant Alibaba, in the city of Wuxi.

Smart building checks

The Centre last year also launched CU-Tech Limited, which provides building inspection services using unmanned systems technology, commonly known as drones.

Professor Chen Benmei and Professor Chen Xi from the Department of MAE, who developed the system, note that there is a sizeable demand for efficient building inspection services in Hong Kong, where about 60% of private buildings are older than 30 years.

Professor Chen Xi says: “Traditionally, the industry needs to erect scaffolding and send workers at heights to identify, with the naked eye or handheld tools, defects on the exteriors of a high-rise. But drones can do a much more accurate, faster and safer inspection. The data collected will help building owners decide whether repair works are needed.”

Their automated inspection and information system can first plan an automated flight path for a few cooperative drones to conduct a comprehensive survey of a building’s facades within a shorter period of time than existing drone systems, which rely on human control.

The system will then evaluate the building’s structural and thermal performance with the assistance of AI. Compared to the traditional method of deploying workers, the system can lower the inspection cost by at least a third and minimise safety risks. The team is in talks with government departments and property management companies about using their services.

‘Power suits’ give workers a boost

Another Centre project, led by Professor Liao Wei-hsin, aims to develop a lightweight, economical robotic exoskeleton for workers in different sectors. Worn over the torso and upper legs, the exoskeleton supports the spine and helps lift heavy loads and prevent injury.

“Lower back pain is the number one occupational injury among industrial workers worldwide,” says Professor Liao, chair of the MAE Department. “Exoskeletons could be widely applied among workers who need to carry heavy loads, such as airport workers, construction workers and hospital nurses, but there is still a lot of room for further research and improvement in existing models to make them more comfortable to wear and easy to move around in.”

The models being developed by his team are built with a magneto-rheological series elastic actuator he invented, which can generate large controllable braking torque while consuming little energy. They also provide assistance with asymmetrical bending that involves axial twisting, a feature that is lacking in most existing products. His team aims to develop a series of new exoskeletons by 2025.

Robots in the future

Looking ahead, Professor Liu says the Centre will work to cater the needs of Hong Kong’s service industry, building robots that can take up tasks such as serving dishes in restaurants and folding blankets in hotel rooms. It is discussing collaboration possibilities with many business partners.

But robots will not be able to take over from humans completely, he cautions. “Human muscles are unique. Presently there is no material available to build robots that are as lightweight as human muscles while outputting the same level of energy.

“What core technology we should develop, and how we define a robot: these are things we are constantly thinking about.”

Reprinted from the Bulletin (No.2, 2023)

Text by Joyce Ng

Main photo by D. Lee